SW (Swing Arm)

Its compact design with sufficient force for a small cutting job. A few selections on cutting force from 10, 15 & 25 Tons.

CUTTING FORCE tons 200 160 130 100 80

MATERIAL WIDTH mm. 2500 2000 1600 1200 900

MATERIAL DEPTH mm. 1500 1200 900 600

SW ( Swing Arm )

Its compact design with sufficient force for a small cutting job. A few selections on cutting force from 10, 15 & 25 Tons.

CUTTING FORCE tons 200 160 130 100 80

MATERIAL WIDTH mm. 2500 2000 1600 1200 900

MATERIAL DEPTH mm. 1500 1200 900 600

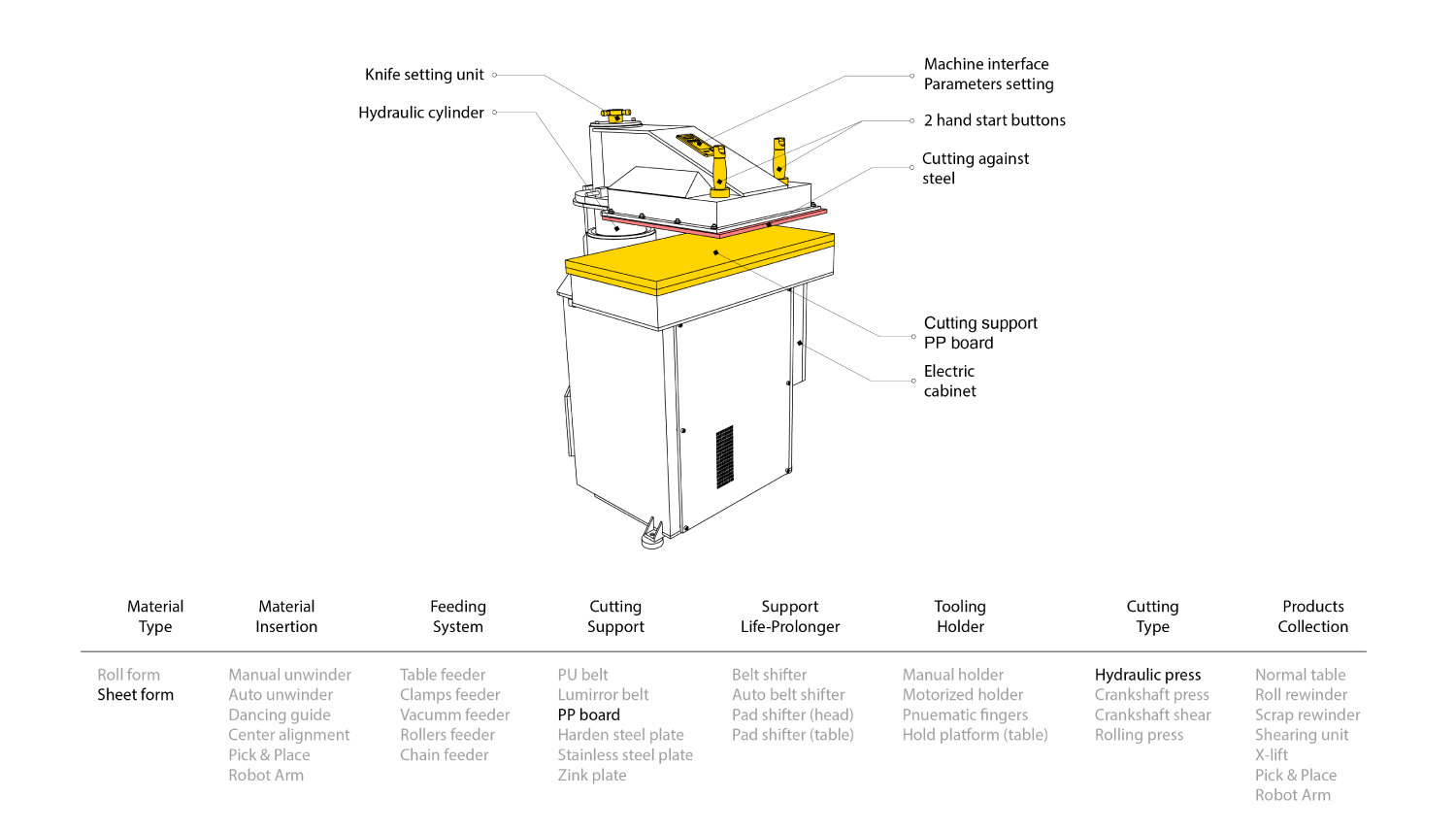

Swing arm is our first model, which has brought us one of the world leaders in cutting hydraulic press. The machine fits broad businesses relevant to cutting especially in footwear industry, automotive industry, hide and leather industry, plastic packaging industry, means that various kind of material is applicable to this machine. Its compact design and ample pressure for a small cutting job satisfies most customers. Yet, the machine provides an utmost with regards to productivity, cost saving and high safety.

The name “Swing Arm” is derived from its appearance as it has a cutting heads, which is able to swing from one side to another. After cutting, the head is swung open to remove cut pieces and to load a new sheet on the table.

A concern of safety is also important, it is necessary to have both hands of a user press on the trigger simultaneously, protecting any part of user’s body get into a dangerous working area, and otherwise, the head plate will not press.

Swing arm is our first model, which has brought us one of the world leaders in cutting hydraulic press. The machine fits broad businesses relevant to cutting especially in footwear industry, automotive industry, hide and leather industry, plastic packaging industry, means that various kind of material is applicable to this machine. Its compact design and ample pressure for a small cutting job satisfies most customers. Yet, the machine provides an utmost with regards to productivity, cost saving and high safety.

The name “Swing Arm” is derived from its appearance as it has a cutting heads, which is able to swing from one side to another. After cutting, the head is swung open to remove cut pieces and to load a new sheet on the table.

A concern of safety is also important, it is necessary to have both hands of a user press on the trigger simultaneously, protecting any part of user’s body get into a dangerous working area, and otherwise, the head plate will not press.

Customization & Option

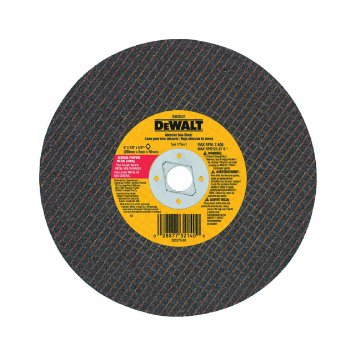

Material & Tooling